Pigment Plant Capital Improvement Projects

Tronox is a global vertically integrated producer of titanium dioxide and inorganic chemicals, which mines and processes titanium ore, zircon and other materials and manufactures titanium dioxide pigment, specialty-grade titanium dioxide products and high-purity titanium chemicals. CPC provides engineering services to Tronox’s West Australian region encompassing the mine (Cooljarloo), dry and synthetic rutile plant (Chandala) […]

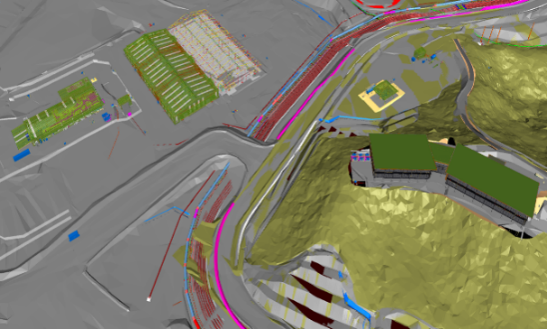

Cobre Panama – Mine and Port Area Infrastructure

From 2017 to 2019, CPC completed EP services for the non process infrastructure requirements on the Cobre Panama Project for First Quantum Minerals. The scope entailed design of facilities at both the Port and Mine sites encompassing the following aspects: Mine and Process Plant non process infrastructure (Workshops, Lube Farms, Tyre Change, Bulk Fuel Storage, […]

Tanami Expansion Project Stage 3

Subsequent to the completion of the pre-feasibility study, CPC was awarded the contract to perform engineering and procurement support services for the Tanami Expansion Project for Newmont Mining Services. This project covered site infrastructure and process plant expansion including comminution and gravity circuits, an additional pre-leach thickener, gold room upgrade, tailings deslime and filtration. Additional […]

Enterprise Nickel Concentrator

The 4.5 Mt/y Enterprise Nickel Project was developed alongside the 55 Mt/y Sentinel Copper Project and made extensive use of the existing copper facilities and infrastructure. The Enterprise plant was designed with considerable flexibility to allow it to treat ore from a variety of sources. The equipment sizing, and pipe configuration allows a choice of […]

Cowal Gold Project Flotation Tail Leach Project

During 2018, CPC completed a brownfields addition for Evolution Mining’s Cowal Project. A new leach circuit was installed, based on diagnostic leaching indicating that 60% of the flotation tails stream is amenable to direct cyanidation. This project included installation of a new 9.5Mt/a circuit to leach flotation tails and detoxification of this stream before pumping […]

Cowal Gold Dual Leach Train Feasibility Study

During 2018, CPC completed a brownfields addition for Evolution Mining’s Cowal Project. A new leach circuit was installed, based on diagnostic leaching indicating that 60% of the flotation tails stream is amenable to direct cyanidation. This project included installation of a new 9.5Mt/a circuit to leach flotation tails and detoxification of this stream before pumping […]

Balama Graphite Project

CPC assisted Syrah Resources with the development of their Balama Graphite Project in Mozambique. CPC completed detailed engineering, procurement, construction support and commissioning services for the project. The processing facility at Balama will produce a dry graphite concentrate that is bagged and trucked off site. Six size fractions will be produced at the Balama concentrator […]

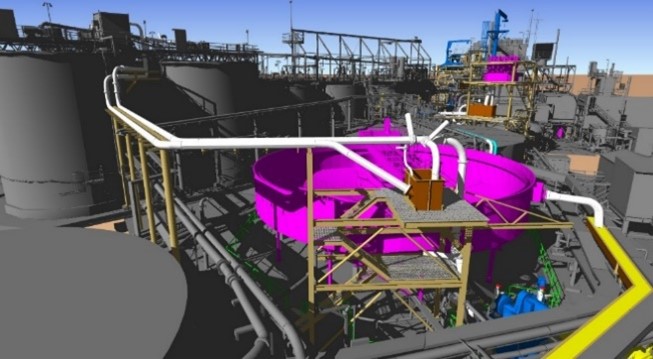

Ravensthorpe Acid Leach Area Project

CPC completed the refurbishment of one complete atmospheric leach tank including engineering and construction activities at First Quantum’s Ravensthope Nickel Operation. Structural steel modifications to a further three tanks has also been completed. This project included the replacement of the acid resistant brick lining, repairs to the structural integrity of the tanks and finite element […]

Guelb Moghrein Regrind and Flotation Project

CPC was engaged by Mauritanian Copper Mines to undertake a study on the brownfield installation of a gravity concentrator at their Guelb Moghrein mine. The aim was to improve recovery of free gold. CPC was awarded the detailed design. The circuit is fed from the ball mill discharge hopper with a pump feeding a gravity […]

Degrussa Crushing Circuit Upgrade

CPC undertook the design, supply and construction of various projects aimed at increasing the recovery of the Sandfire Resources Degussa Copper Mine process plant. These included the expansion of the crushing and flotation circuits. The flotation circuit comprised of the installation of an Eriez 4.27 m diameter by 10.0 m high cleaner scalping column in […]